Excellence without compromise

With over 30 years of innovation and excellence in metal processing, Metal CN excels in creating tailor-made solutions and delivering exceptional finished products.

Process

Quality First. A customer-focused approach.

-

01. Preparation & Optimization

Our technical and commercial team collaborates to identify your needs and optimize the quality, cost, deadlines and choice of materials. Every detail is carefully considered.

-

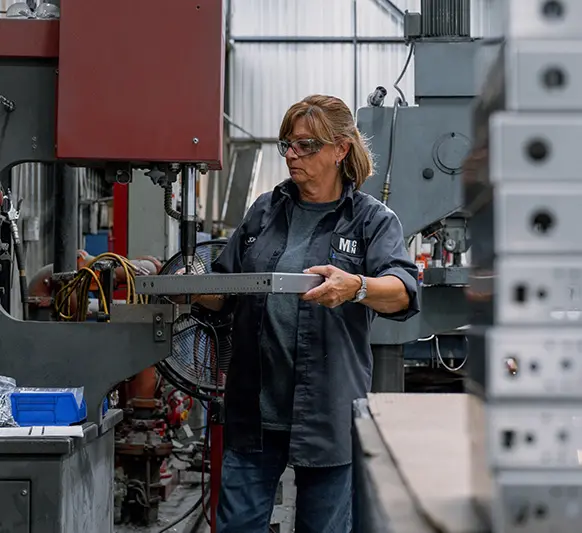

02. Transformation

Our highly qualified team masters complex laser cutting, punching and bending projects thanks to our state-of-the-art machines.

-

03. Welding, Assembly & Finishing

Neat welds, vibrant paint and a rigorous quality assessment ensure that each piece from our workshop exceeds your expectations, demonstrating our commitment to quality and customer service.

Expertise

Discover our fields of expertise

CAD-CAM

Using software like Solid Edge and Metalix, each design is finely optimized.

Laser cutting

Our advanced CNC machines perform precise laser cuts, opening possibilities for steel, stainless steel, and aluminum.

Punching

Our advanced machines custom punch up to 1/4” thickness and 60” width, realizing a variety of projects.

Tube cutting

Our laser can cut metal tubes of different formats and materials with accuracy and speed.

Bending

Our press brakes can transform metal into complex pieces. We bend sheets up to 14’ 2” long.

Welding

Our welders master MIG and TIG techniques, creating strong metal assemblies and finishes.

Assembly

Our crimping equipment allows for the installation of hardware elements, facilitating your assemblies.

Electrostatic painting

Our electrostatic paint system can accommodate parts up to 20’ long.

Materials

A wide range of top quality materials

Aware of the uniqueness of each project, we offer a range of top quality materials to satisfy all your requirements.

- CRS steel

- HRS steel

- Aluminum

- HRPO steel

- M.S. steel.

- Copper

- Mill Finish stainless steel

- Stainless steel 304 #4

- Brass

- 2B stainless steel

- Galvanized steel

- Bronze

- Satin steel

Machines

Harnessing the power of precision

Metal CN is equipped with high-performance equipment and regularly renews them in order to always be at the cutting edge of technology.

Amada ENSIS-3015AJ 6KW

Fiber laser cutting

- Maximum sheet size: 60” x 120”

- Laser power of 6,000 W

- Automated loading/unloading system

Amada FO MII RI 3015

Laser cutting (sheets + tubes)

- Possibility of cutting tubes or pipes with precision

- Cuts up to 8” in diameter for the tube

- Cast iron chassis for greater stability

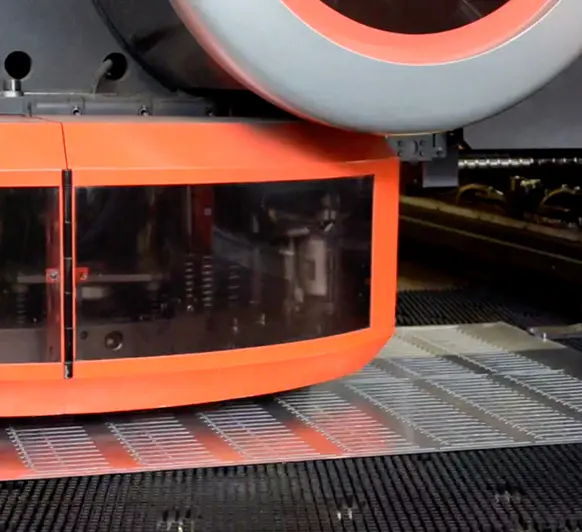

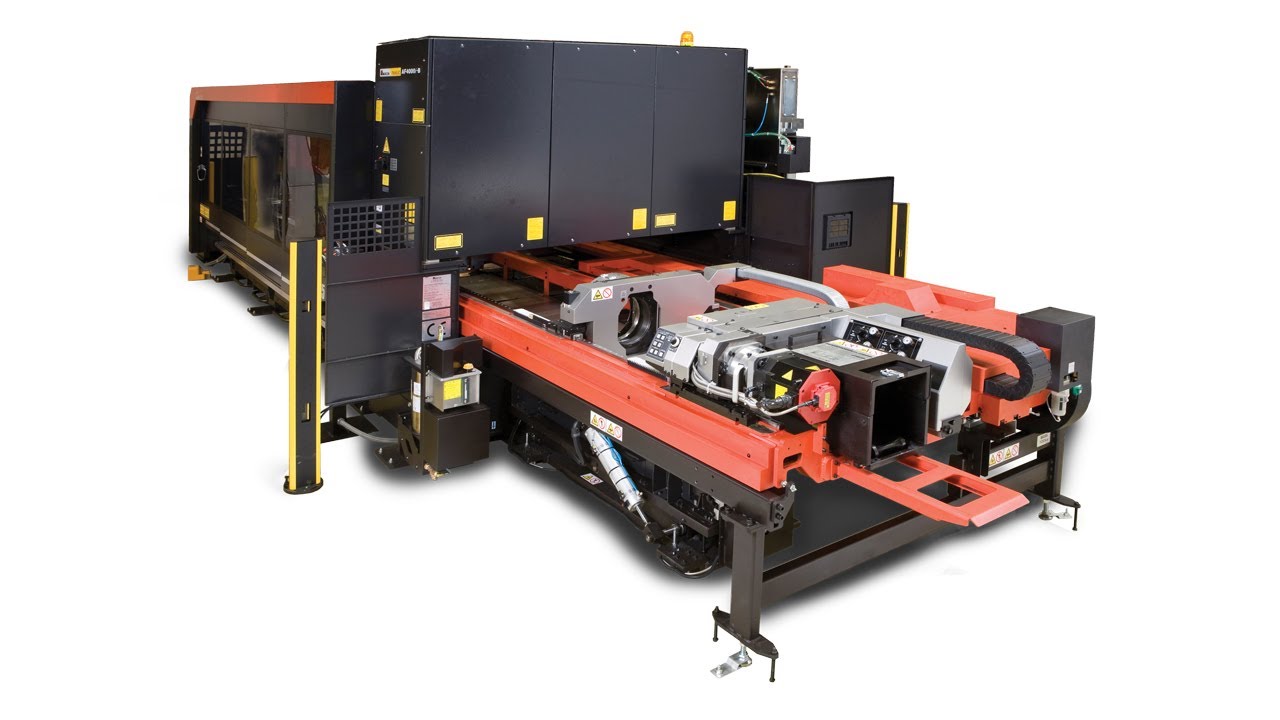

AMADA EML K3610 NT

Punch/Laser Combo

- Press capacity: 30 tonnes

- Laser power: 2,500 W

- Maximum sheet size: 120” x 74”

- Turret rotation speed: 30 RPM

Bystronic Xpert 250

Bender

- Folding up to 160”

- 6 digital axes

- 250 tonnes capacity

Submission

Solutions for impossible projects

Career Opportunities

Join the Metal CN team!

Join Metal CN, where creativity and ingenuity shape our success. Be part of a team that is reinventing metal processing.